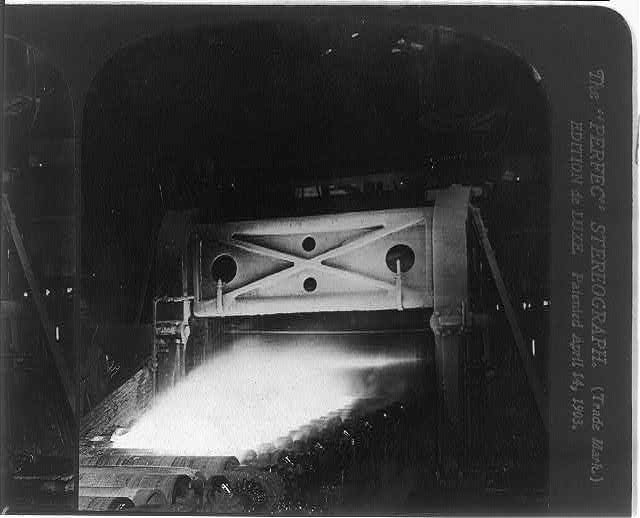

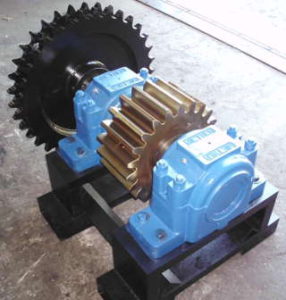

As molten billets of steel race through the plant, they are formed into their final shape through a series of ever tightening rolls and presses.

The stands that hold these forming rolls are under extreme stresses as they progressively squeeze the metals into shape; be it flat sheets, bars, round stock or rails.

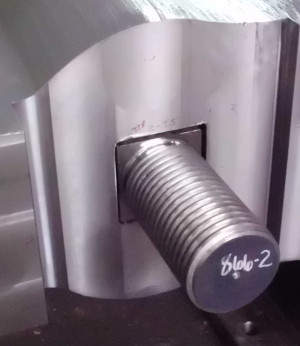

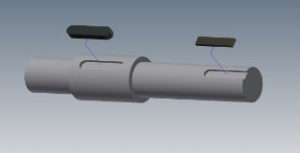

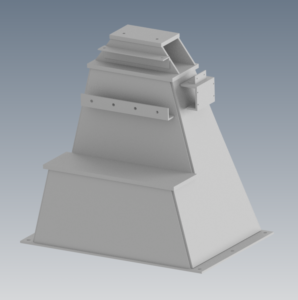

At the top of these stands are the mill caps – holding the components together, absorbing constant shock and vibrations as they maintain pressure on the searing metal as it is is worked beneath it.

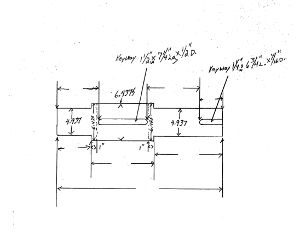

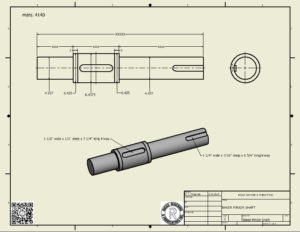

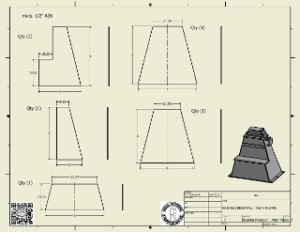

The original cap was a cast part. This machined version will be stronger and less susceptible to cracks and weak spots due to the possibility of bad casting. It is also made of a finer grade of metal than the old, worn piece.

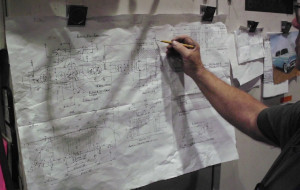

Using the drawings, we will CNC a new component from a 22 inch burn-out weighing over 19,000 lbs. (Not many suppliers can provide a single piece of metal that large.) Hooks were welded on the sides so the block could be moved throughout the shop.

These higher quality mill caps will provide a better support system and a more dependable and stable stand. In the long run, they will help provide our client produce a better product and maintain a longer running mill.

Riggs Machine & Fabricating – Serving industry in KY, OH and WV for over 45 years!