Tri-State MetalTech Expo featured small metalworking businesses from the area. We ran into some old friends and made a few new ones. It was a great way to do some networking. The event was presented by Marshall University’s Advanced Manufacturing Center, Advantage Valley and the WV Development Office. Though it was the first year of the event and we weren’t sure what the turn out would be, we were glad we attended.

The Advanced Manufacturing Center (previously called the Robert C. Byrd Institute) also had their students make their rounds and meet some prospective employers (and we were happy to meet them). These new machinists and machine operators are the life blood of our business and the future of the industry.

We hope to meet with a few of them again as they get closer to the end of their studies.

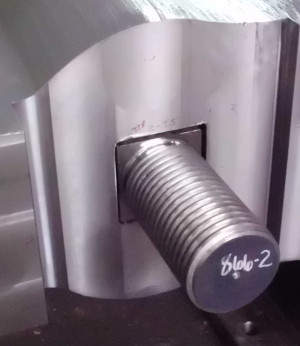

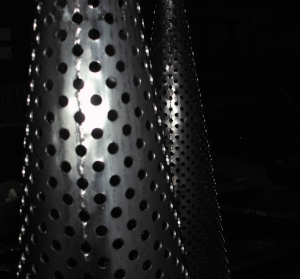

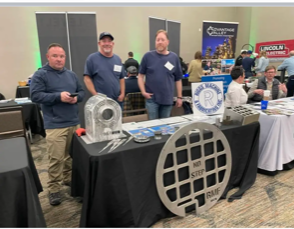

We brought a few sample items along to show off what we do and enjoyed talking up our capabilities to the visitors.

We look forward to more events like this.

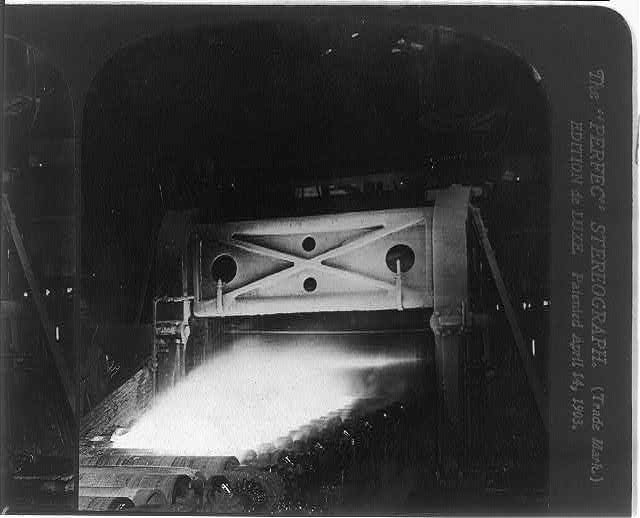

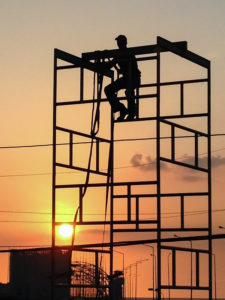

Nucor, who is building a 3.1 billion dollar sheet steel mill in Mason county, WV, was the special guest and had a discussion about doing business with them.

Riggs Machine & Fabricating – Serving industry in KY, OH and WV for over 45 years!