Ever lose a bolt while working on your car, and then have a hard time finding it? Imagine that while working on industrial piping. Well it happens. When a new pipe goes up, many items can find their way trapped in the pipe, and when the unit is first started up, those items go racing to the end of the pipes. Many times leading into a unit or a pump.

A simple bolt in a new pump is a recipe for disaster. The pump is blown. It has to be removed and repaired. They are often in hard to access locations, covered with guards and shrouds. Crews come in! Permits! Downtime! Behind schedule!

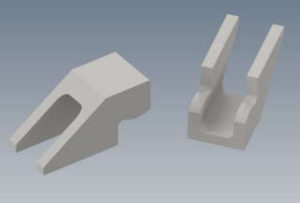

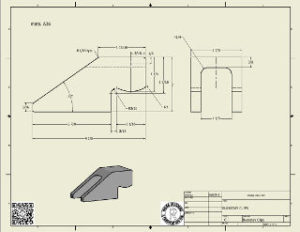

But this simple item could have prevented that. The Witch Hat Strainer (also called a Start-Up Strainer), is placed in-line to catch items like bolts, nuts, tools, debris and anything that may have found it’s way in the line during installation or maintenance.

A novel idea that saves time and money.